Transition Leadership Stories

Original voices, thoughts, approaches and accomplishments from leaders in transition.

Profiling diverse perspectives on the transition to a low carbon, socially equitable economy from business, academia, government and the non-profit community.

Transition Leadership Series: Episode 3

In 1684, the steam engine revolutionized the way in which economies functioned, allowing for the extraction and delivery of raw materials at rates unimaginable by previous generations. With accelerated industrialization, the world began to fall into ecological overshoot, consuming natural resources faster than the Earth’s capacity to renew them.

Today, it is estimated that we are consuming the planet’s resources 1.75 times faster than nature can renew them, creating what’s called an ‘ecological deficit’.

The good news is that the current trend can be reversed. The Global Footprint Network and Schneider Electric believe that ‘one-planet compatibility’ is “not only within reach, but it is the strategic compass that can guide businesses to their own long-term success.”

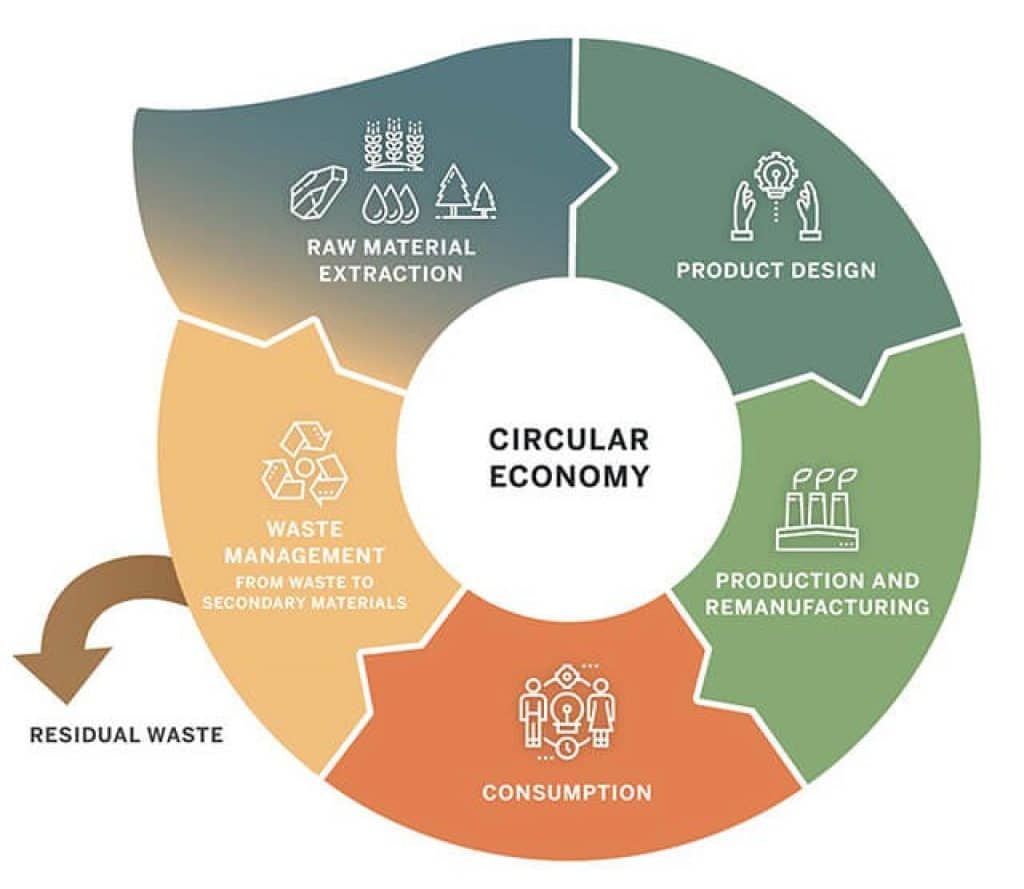

How is industry meeting this resource challenge? Through innovative efficiency strategies and circular production models, they are maximizing and redefining value across their supply chains.

Implications for business

As concern around resource availability grows, organizations are facing increased pressure to offer goods and services in balance with what the Earth’s ecosystems can provide. While the pressure to ‘go green’ may be incentive enough for some, there are other exciting drivers for change. The Ellen MacArthur Foundation reports that applying circular economy principles could unlock up to EUR 1.8 trillion of value for Europe’s economy. Reducing costs through efficiency maximization, capturing market shifts in favour of sustainable technologies, and securing financing from investors who increasingly value transition are just a few of the opportunities that accompany this shift.

Research also indicates that companies with business models that increase human well-being and resource security are much more likely to be economically successful in the long-run than those companies that are incompatible with one-planet prosperity.

We’re using up resources more than they can be regenerated. We’re borrowing from the future to live in the present, living off credit. At some point we’re going to have to pay the bill.

Adeline Murthy

Global Footprint Network

Replicable Strategies for Success

Looking to capitalize on these opportunities, forward-thinking companies are “closing the loop” by exploring circular economic models: circulating products, parts and materials between customers and suppliers. From food to fashion, multinational corporations and scrappy start-ups alike are intensifying their pursuit of circular principles.

For example, technology manufacturer Philips set the goal of closing the loop on all of their large medical systems equipment and extending circular practices to all medical equipment by 2025, all while committing to a 90% waste diversion rate. Their take-back program for end-of-life upcycling was accelerated with the development of partnerships with other technology firms on a circular model for e-waste by collecting, recovering and reusing electrical and electronic equipment in their products. They describe their supply chain shift as a move from the linear model of ‘Take › make › dispose’ to a circular model of ‘Make › use › return’ in four returning loop: service, refurbish, parts recovery, recycle.

Another way to pursue a circular business model is by offering sharing platforms or products as a service. Organizations like the Toronto Tool Library and the Fresh Fashion Library offer customers access to, rather than ownership of products. Dutch startup Bundles offers high-end washing machines, dryers, dishwashers and coffee machines as a subscription service to conscious consumers.

Customers are charged a monthly fee based on usage, as tracked through a smart plug. Machines are maintained and repaired by Bundles who also upcycles and recirculates them at what would have been their ‘end of life’. This model opens up new opportunities for growth and cost savings, reduces resource risk, and facilitates smart asset management.

Join the movement

Waste, pollution and overconsumption are not imperatives to economic growth or stability. They are simply the consequences of decisions made in a time where resources were seemingly infinite. Following the examples of leading businesses and governments, we are called to design and implement restorative and regenerative practices that reflect 21st century realities, living and creating within the boundaries of our one planet.

To learn more about opportunities to participate in the transition to a low-carbon economy, sign up for ASI quarterly newsletters.

Nicole Doray

Manager, Social Impact & Strategic Innovation